AARA INFRA PRODUCTS specializes in manufacturing custom MS foundation bolt solutions tailored to meet specific project needs across industries. Our MS foundation bolt is engineered with precision using high-grade mild steel (MS), ensuring superior strength, durability, and performance in structural anchoring applications.

Whether you need a standard or customized design, our MS foundation bolt can be manufactured in various shapes, including L-type, J-type, U-type, T-type, and Eye-type, depending on your foundation requirements. Every MS foundation bolt from AARA INFRA PRODUCTS is produced with strict quality control to ensure excellent load-bearing capacity and corrosion resistance.

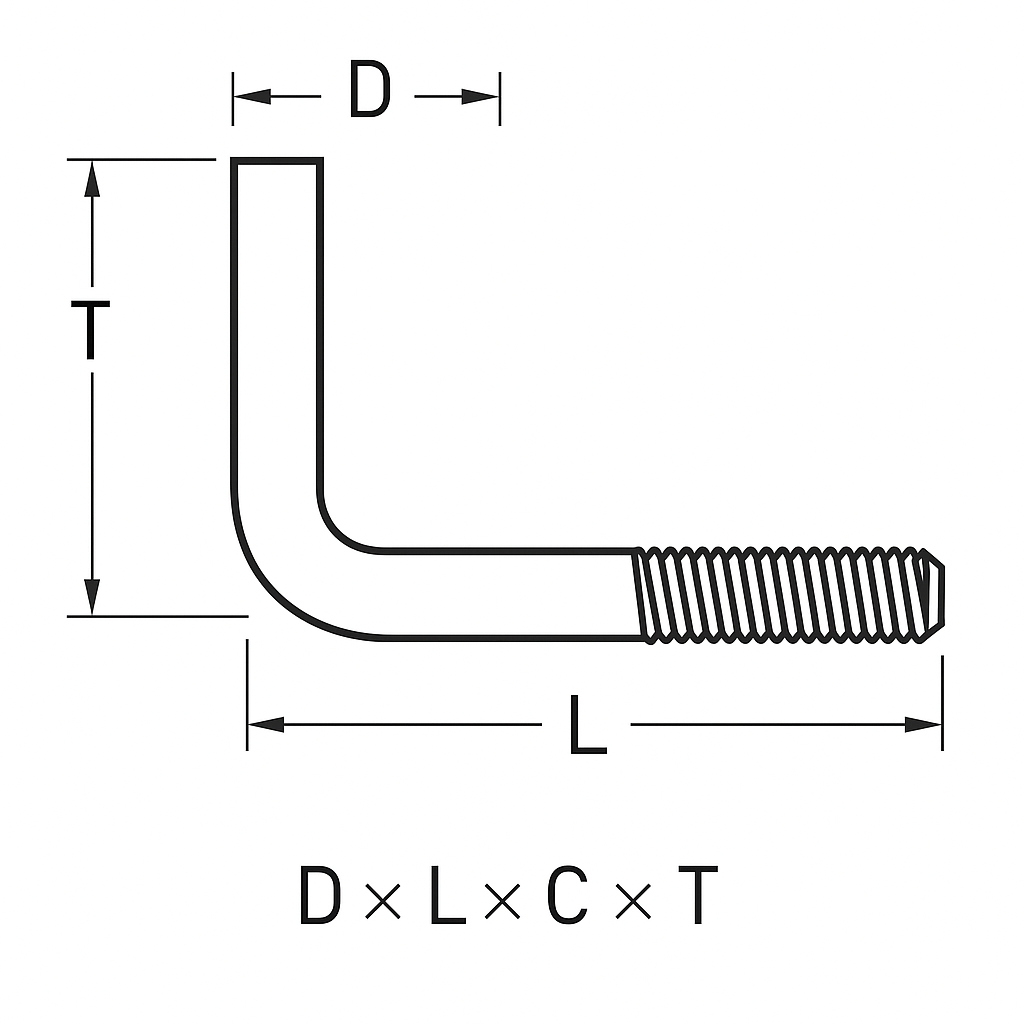

We offer complete customization on thread length, diameter, bend angle, and surface finish to match your application environment. Each MS foundation bolt undergoes precision threading and surface treatments such as galvanizing, zinc plating, or blackening based on client specifications.

Our MS foundation bolt is widely used in infrastructure projects, heavy machinery installations, steel structures, and power plant foundations. AARA INFRA PRODUCTS ensures that each MS foundation bolt meets industry standards for strength, reliability, and longevity.

If your project demands a trusted and durable anchoring solution, choose our custom MS foundation bolt for unmatched performance. AARA INFRA PRODUCTS is committed to delivering high-quality MS foundation bolt solutions with on-time delivery and exceptional service.

Reach out today to discuss your MS foundation bolt requirements and experience quality that holds strong—always.

Why choose us

On-time delivery

Competitive Price Guarantee

Top Product

100% customer satisfaction

Key Features

- Tailor-Made Designs: Available in various shapes like L-type, J-type, U-type, Eye-type, and T-type based on project needs.

- Material Flexibility: Manufactured from high-quality MS (Mild Steel), stainless steel, or high-tensile steel.

- Thread Customization: Thread length and diameter can be adjusted as per load requirements.

- Corrosion Resistance: Options for hot-dip galvanizing, zinc plating, or epoxy coating.

- Precision Manufacturing: CNC threading and bending ensure exact dimensional accuracy.

- Compliance: Manufactured as per IS, ASTM, DIN, or customer-specific standards.

Technical Specifications

| Attribute | Details |

|---|---|

| Material | Mild Steel, Carbon Steel, Stainless Steel, Alloy Steel, as per customer requirement |

| Grade | 4.6, 5.8, 8.8, 10.9, En8, IS2062, as per requirement |

| Shape | L, U, J, T, Eye, Y, Plate, Pipe Stiffener, Sag Rod, Custom |

| Size | Diameter: M12 to M65 mm or ½” to 2.1/2” Length: up to 3000 mm |

| Thread Type | Metric, BSW, UNC as per customer requirement |

| Thread Length | up to 500 mm |

| Surface Finish | Black, Galvanized Zinc, Hot Dip Galvanized, Paint, Red Oxidize, as per customer requirement |

| Country of Origin | INDIA |

| Usage | Industrial, Construction, Automotive Parts |

Applications

- Anchoring heavy machinery and structural supports

- Construction of bridges, dams, power plants, and industrial sheds

- Base plate connections in steel structures

- Wind turbines, transmission towers, and pipelines

- Oil & gas, railway, and marine infrastructure

- Foundation support for precast concrete structures

Advantages

- Strong Anchorage: The eye design offers enhanced grip in concrete and eliminates slippage.

- Enhanced Strength: Designed to provide high tensile and shear strength.

- Quick Installation: Delivered ready-to-use with pre-threaded ends and protective coatings.

- Versatile: Suitable for dynamic load-bearing in a wide range of industries.

- Long-Term Performance: Withstands environmental stress, vibration, and corrosion..

Manufacturing Process

-

Requirement Analysis

Custom specs reviewed and design finalized.

-

Raw Material Selection

Mild steel or other alloys chosen based on strength needs.

-

Cutting and Shaping

Rods are cut and bent into the desired type using hydraulic presses.

-

Threading

Threads are machined or rolled onto the opposite end..

-

Surface Treatment

Galvanization or coating applied for protection.

-

Quality Inspection

Dimensional and strength checks performed to meet standards.

-

Packaging and Dispatch

Bolts are packed securely and delivered as per project timelines.