AARA INFRA PRODUCTS is a trusted manufacturer of high-quality Sag Rod and Both End Thread Bolt solutions, engineered for strength and durability in critical industrial and infrastructure applications. Our Sag Rod is designed for use in power transmission lines, providing the necessary tension and support to maintain the stability of wires and cables. Made from premium-grade materials such as mild steel, our Sag Rod is designed to withstand harsh environmental conditions and heavy loads.

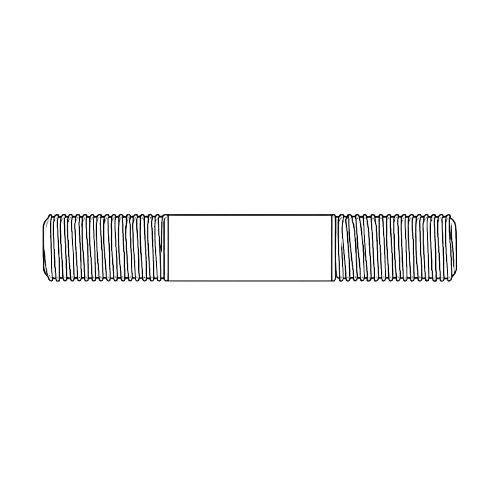

The Both End Thread Bolt is also a vital part of our offerings, designed for use in structural applications requiring secure fastening at both ends. This versatile bolt ensures secure connections for a wide range of installations, including electrical towers, construction projects, and machinery. With precision threading at both ends, the Both End Thread Bolt provides a tight, reliable fit for any setup.

Both the Sag Rod and Both End Thread Bolt are manufactured with a focus on quality, using cutting-edge technology and high-strength materials to ensure optimal performance. They are rigorously tested for strength, durability, and corrosion resistance, making them ideal for heavy-duty use in outdoor and industrial environments.

Whether you need a Sag Rod for power line support or a Both End Thread Bolt for structural integrity, AARA INFRA PRODUCTS provides custom solutions to meet your specific needs. Contact us today for more information or to place your order for high-quality Sag Rod and Both End Thread Bolt.

Why choose us

On-time delivery

Competitive Price Guarantee

Top Product

100% customer satisfaction

Key Features

- High Strength: Made from high-quality mild steel, designed to endure heavy tension loads.

- Corrosion Resistance: Available with galvanization or coating to protect against rust and corrosion, ensuring long-lasting durability.

- Adjustable Lengths: Custom lengths and sizes are available to meet specific project requirements.

- Precision Engineering: Manufactured with accurate dimensions for a perfect fit in transmission lines and other structures.

- Easy Installation: Designed to be lightweight yet strong, making installation easier and more efficient.

- Weather Resistance: Built to withstand harsh weather conditions, ideal for outdoor and aerial installations.

Technical Specifications

| Attribute | Details |

|---|---|

| Material | Mild Steel, Carbon Steel, Stainless Steel, Alloy Steel, as per customer requirement |

| Grade | 4.6, 5.8, 8.8, 10.9, En8, IS2062, as per requirement |

| Shape | L, U, J, T, Eye, Y, Plate, Pipe Stiffener, Sag Rod, Custom |

| Size | Diameter: M12 to M65 mm or ½” to 2.1/2” Length: up to 3000 mm |

| Thread Type | Metric, BSW, UNC as per customer requirement |

| Thread Length | up to 500 mm |

| Surface Finish | Black, Galvanized Zinc, Hot Dip Galvanized, Paint, Red Oxidize, as per customer requirement |

| Country of Origin | INDIA |

| Usage | Industrial, Construction, Automotive Parts |

Applications

- Power Transmission Lines: Used to maintain proper tension and support of wires.

- Telecommunication Towers: Ensures the structural integrity of the transmission lines.

- Electrical and Utility Installations: For stabilizing cable systems in power plants, substations, and utility stations.

- Construction Projects: As a tension support rod in various heavy-duty applications.

- Street Lighting: Used in holding up power cables for public infrastructure projects.

- Wind Turbines and Other Large-Scale Structures: To secure cables and wires in high-tension environments.

Advantages

- Enhanced Durabilit: The galvanization or coating ensures the Sag Rod performs reliably in harsh environments, even in coastal or industrial areas.

- High Load Capacit: Designed to handle heavy tension, making it ideal for power transmission lines and high-tension cable applications.

- Customizable: Available in different lengths, diameters, and finishes to suit specific needs.

- Cost-Effective: A durable solution that reduces the need for frequent replacements or repairs.

- Cost Effective: Long life and minimal maintenance make it an economical choice.

- Simple Maintenance:Low maintenance requirements, making it a convenient and efficient solution for long-term use.

Manufacturing Process

-

Material Selection

High-quality mild steel or other alloys are chosen based on strength and durability requirements.

-

Cutting

Rods are cut to the required lengths and shaped accurately to specification.

-

Bending

A mechanical or hydraulic press bends one end into an eye shape.

-

Threading

Both ends are precisely threaded to ensure proper installation and attachment to other components

-

Heat Treatment

If necessary, the rods undergo heat treatment to improve tensile strength..

-

Surface Finishing

A galvanization or zinc-plating process is applied for corrosion resistance, ensuring long-term durability.

-

Quality Inspection

Each Sag Rod undergoes rigorous testing for dimensional accuracy, tensile strength, and coating quality.

-

Packaging

Finally, the Sag Rods are packed securely and delivered to customers according to project timelines.