Sleeves

Sleeves are cylindrical pipe components used in conjunction with foundation bolts to improve alignment, prevent bending during casting, and facilitate bolt installation in deep concrete foundations. They are often placed over anchor rods to allow movement, vibration absorption, and easy bolt replacement.

Key Features

- Used to protect and align anchor bolts

- Available in GI, MS, or PVC material

- Reduces stress and bending on embedded bolts

- Enhances bolt removal and realignment after casting

- Supports custom length, diameter, and slotting

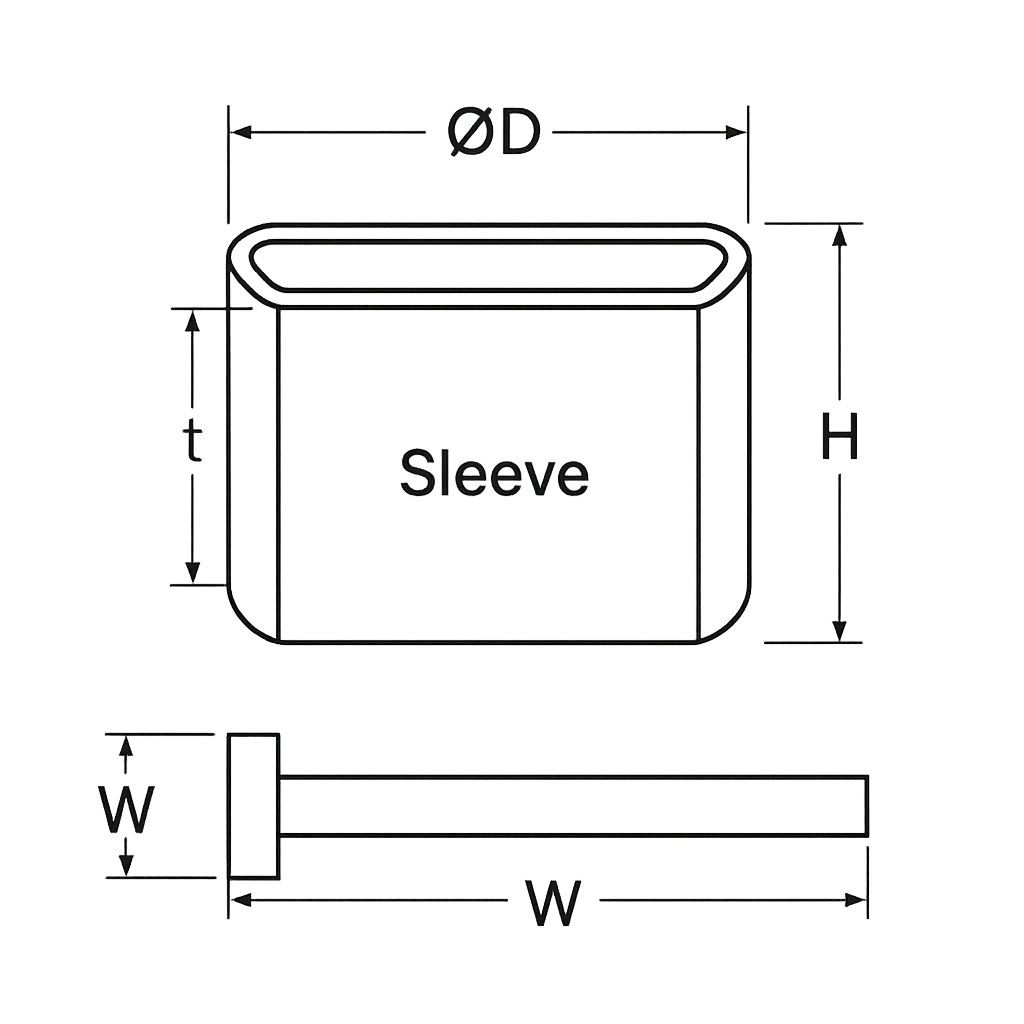

Technical Specifications

- Size (ID x Length): ID from 20mm to 100mm | Length up to 1000mm

- Material Options: GI (Galvanized Iron), Mild Steel, PVC

- Shape: Round (standard), square or slotted (optional)

- Wall Thickness: 1.6mm to 5mm

- Surface Finish (if MS): Zinc Plated / HDG / Painted

- Slotting Options: For slip-fit or adjustable bolt systems

- Standards: IS/ASTM pipe and alignment tolerances followed

Manufacturing Method & Tolerances

Manufacturing Method:

Sleeves are cut from standard or custom steel/GI pipes. Additional machining, slotting, or capping can be done as required. Finishing is applied for corrosion protection in exposed environments.

Tolerances:

- ID/OD: ±0.5mm or as per pipe spec

- Length: ±1mm

- Custom cutting and slotting as per drawing

Applications & Usage

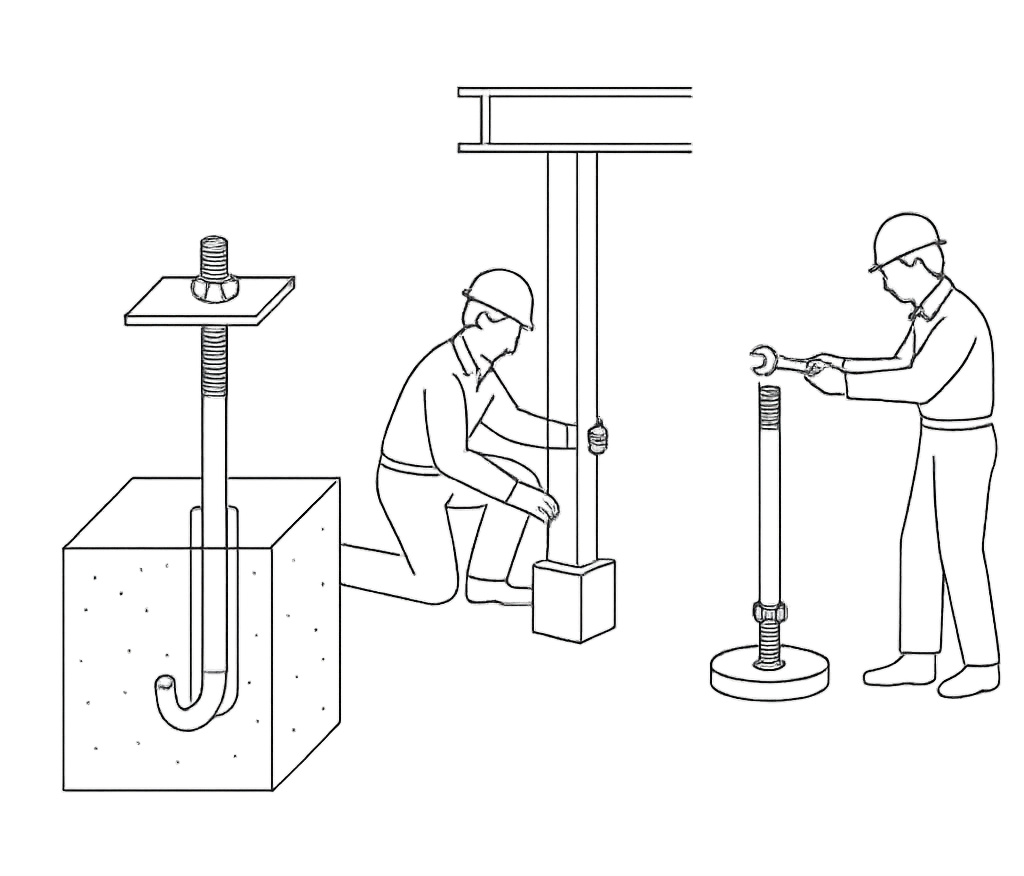

- Used in substation foundations and deep anchor settings

- Helps in post-tension anchor bolt alignment

- Prevents bolt damage during concrete pouring

- Used in column bases, pole foundations, and base plates

- Ideal for foundation systems requiring bolt replacement access

Need customized sleeves for your foundation bolts?

We manufacture foundation sleeves in GI, MS, and PVC — in your specified sizes, slots, and finishes.

Send Your Requirements