Washers

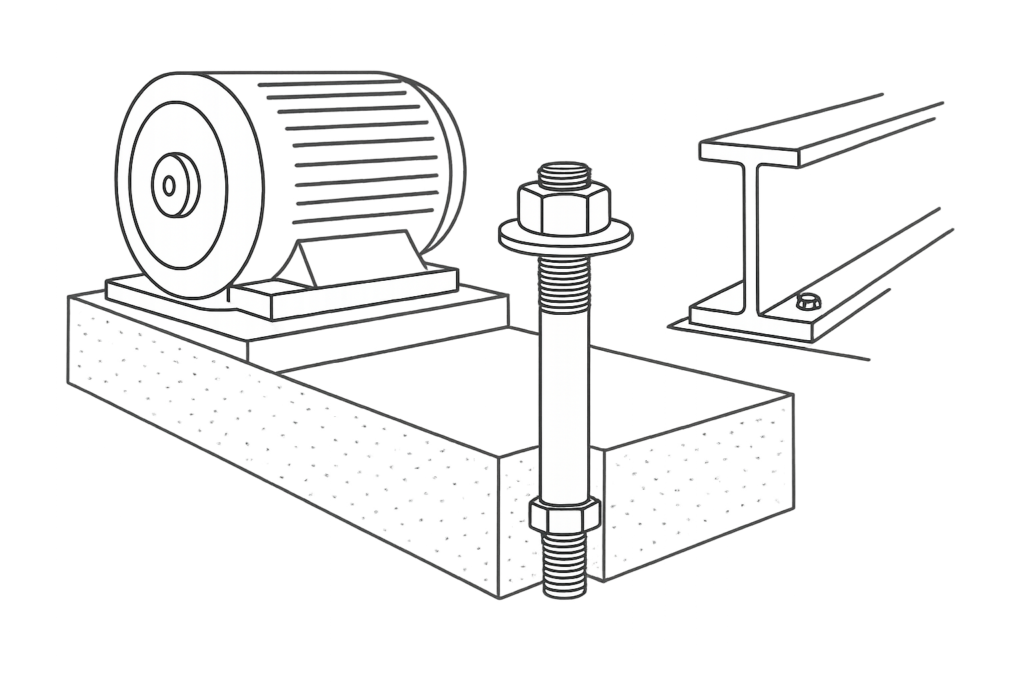

Washers are essential components in bolted connections, providing a smooth bearing surface to distribute loads, prevent damage, and maintain bolt tension. Available in plain, spring, and heavy-duty types, washers are widely used in foundation anchoring systems to ensure structural integrity and long-term performance.

Key Features

- Helps distribute load and prevent surface damage

- Available in flat, spring, and beveled designs

- Compatible with anchor bolts, rods, and nuts

- Made from mild steel, stainless steel, and hardened steel

- Coated for corrosion resistance and durability

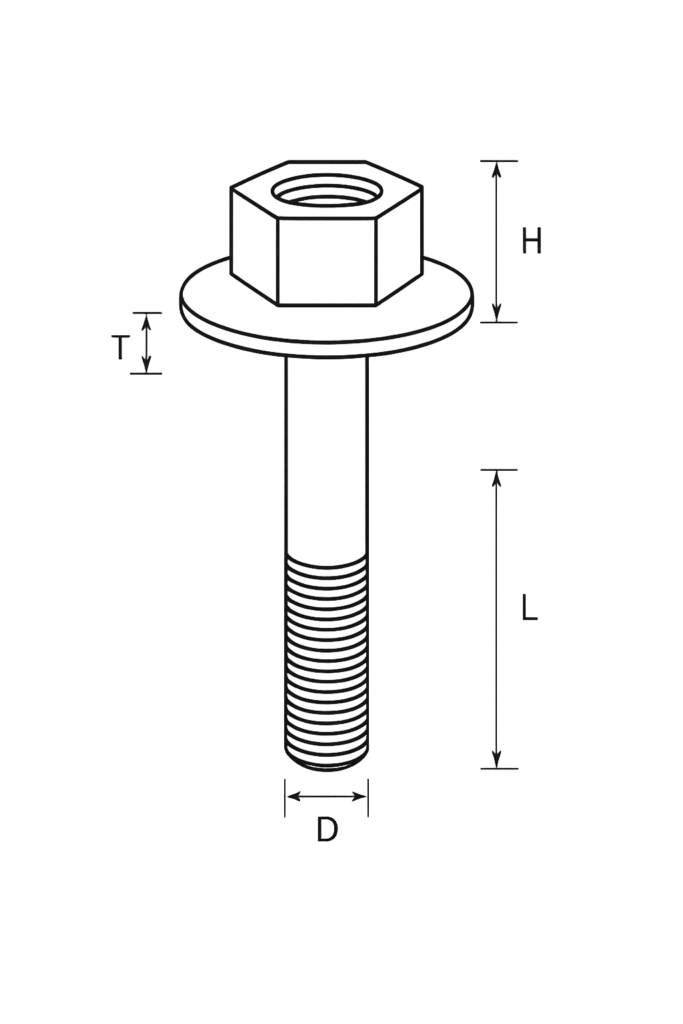

Technical Specifications

- Size (ID x OD x Thickness): M12 to M76 | Custom as required

- Material Grade: MS, EN8, SS304, SS316, Spring Steel

- Washer Type: Plain (Flat), Spring, Tapered, Beveled

- Surface Finish: Zinc-plated, Hot-Dip Galvanized, Black

- Standards: IS 2016, DIN 125/127, ASTM F436

- Custom Shapes: Available on request (square, rectangular)

- Compatibility: All standard foundation bolts and studs

Manufacturing Method & Tolerances

Manufacturing Method:

Washers are blanked or laser-cut from sheet metal or forged bar, then machined or flattened to meet dimensional tolerances. Heat treatment and coating are applied based on mechanical or environmental demands.

Tolerances:

- ID & OD: As per IS / DIN standard

- Thickness: ±0.3mm or per drawing

- Surface finish: Coating thickness as per ISO 10684 / ASTM

Applications & Usage

- Used with foundation bolts and rods for load distribution

- Prevents bolt head/nut embedding into surfaces

- Common in tower bases, machinery footings, and plates

- Ensures bolt tension in vibrating structures

- Found in power plants, bridges, and infrastructure installations

Looking for standard or heavy-duty washers?

We supply all types of foundation washers — flat, spring, beveled — in your required sizes, materials, and finishes.

Send Inquiry