AARA INFRA PRODUCTS is a leading manufacturer of high-quality Plate Type Foundation Bolt and Heavy Duty Foundation Bolt, designed to provide strong, durable, and reliable anchoring solutions. Our Plate Type Bolt is engineered for applications requiring enhanced stability and load-bearing capacity. Crafted from premium materials like mild steel or high-tensile steel, the Plate Type Bolt ensures long-lasting performance in various demanding environments.

The Heavy Duty Foundation Bolt is specifically designed to withstand high stress and heavy loads, making it ideal for infrastructure projects, industrial machines, and steel structures. Both the Plate Type Bolt and Heavy Duty Foundation Bolt are available in various sizes, with customizable lengths, diameters, and coatings to meet specific project requirements.

At AARA INFRA PRODUCTS, we understand that the strength of your foundation is paramount. Our Plate Type Foundation Bolt and Heavy Duty Foundation Bolt undergo rigorous quality checks to ensure precision, durability, and resistance to corrosion, ensuring optimal performance in even the toughest conditions. These bolts are widely used in the construction of power plants, bridges, and heavy-duty machinery installations.

If you’re looking for a Plate Type Bolt or Heavy Duty Foundation Bolt that delivers strength and reliability, AARA INFRA PRODUCTS is your trusted solution. Reach out today to discuss your requirements and experience the quality and service that make us leaders in the field.

Why choose us

On-time delivery

Competitive Price Guarantee

Top Product

100% customer satisfaction

Key Features

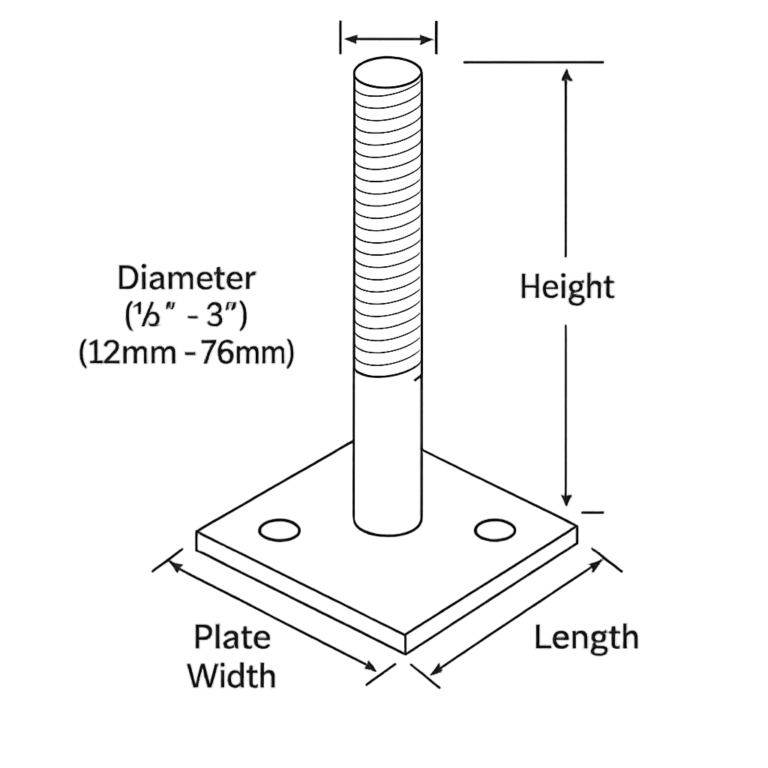

- Shape: Consists of a threaded rod with a flat or specially shaped plate welded or attached to one end.

- Material: Made from high-strength materials like carbon steel, alloy steel, or stainless steel for durability.

- Coating: Hot-dip galvanization, zinc plating, or epoxy coatings are commonly applied for corrosion protection.

- Customizable: The size, plate dimensions, and thread specifications can be tailored to specific application needs

Technical Specifications

| Attribute | Details |

|---|---|

| Material | Mild Steel, Carbon Steel, Stainless Steel, Alloy Steel, as per customer requirement |

| Grade | 4.6, 5.8, 8.8, 10.9, En8, IS2062, as per requirement |

| Shape | L, U, J, T, Eye, Y, Plate, Pipe Stiffener, Sag Rod, Custom |

| Size | Diameter: M12 to M65 mm or ½” to 2.1/2” Length: up to 3000 mm |

| Thread Type | Metric, BSW, UNC as per customer requirement |

| Thread Length | up to 500 mm |

| Surface Finish | Black, Galvanized Zinc, Hot Dip Galvanized, Paint, Red Oxidize, as per customer requirement |

| Country of Origin | INDIA |

| Usage | Industrial, Construction, Automotive Parts |

Applications

- Heavy Machinery Foundations: Provides robust anchoring for equipment that generates significant vibrations.

- Structural Anchoring: Secures steel frames, columns, and girders in construction projects.

- Industrial Infrastructure: Commonly used in refineries, power plants, and manufacturing units.

- Large-Scale Civil Projects: Suitable for dams, bridges, and retaining walls where heavy loads are expected.

Advantages

- Enhanced Anchoring: The plate increases the surface area embedded in concrete, improving load distribution and resistance..

- High Durability: Made from materials that withstand heavy loads and harsh environments.

- Corrosion Resistance: Coatings protect the bolt in corrosive conditions.

- Versatility: Can be designed for a wide range of applications and loads

Manufacturing Process

-

Material Selection

High-quality steel is chosen for strength and reliability.

-

Cutting

Steel rods are cut to the required length.

-

Bending

A mechanical or hydraulic press bends one end into an eye shape.

-

Threading

The other end of the rod is threaded for attaching nuts and washers.

-

Heat Treatment

Bolts are heat-treated to improve strength (if required).

-

Surface Finishing

Protective coatings are applied to resist corrosion.

-

Quality Inspection:

Dimensional and strength checks performed to meet standards.

-

Packaging

Packaged and labeled for easy identification and transport.